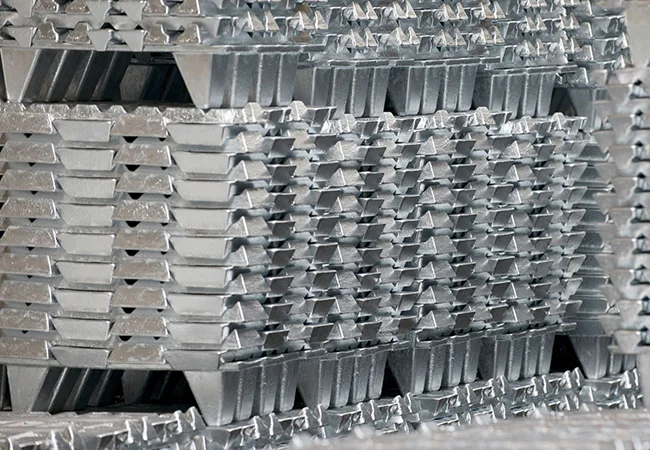

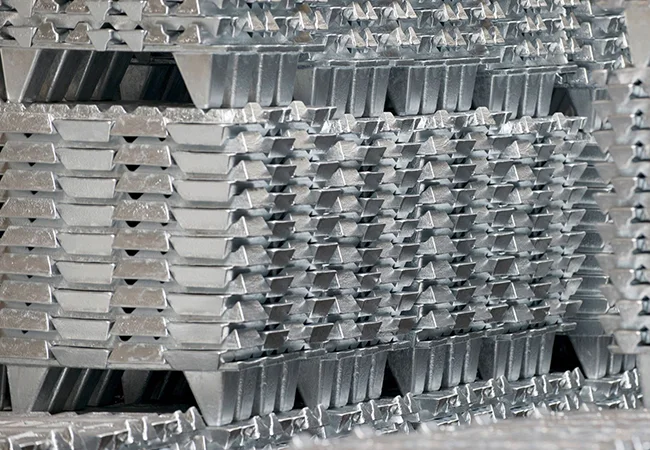

Zamak 4 / ZA-4

Zamak 4 was developed for the Asian markets to reduce the effects of die soldering while maintaining the ductility of zamak 3. This was achieved by using half the amount of copper from the zamak 5 composition

When compared to Zamak 3, the mold sticking problem is improved and the flexibility remains unchanged. It is commonly used to produce clothing accessory such as zipper pulls and zipper sliders.

Zamak 4 was developed for the Asian markets to reduce the effects of die soldering while maintaining the ductility of zamak 3

• High strength-to-weight ratio and good ductility

• Better in mold adhesion problems encountered with Zamak 3

• Good performance on clothing accessories such as zipper sliders and zipper pulls

Zamak 4 Chemical Analysis

| Analysis ( %) | Zamak 4 / ZA-4 |

|---|---|

| Al | 3.9 – 4.3 |

| Cu | 0.3 – 0.5 |

| Mg | 0.03 – 0.06 |

| Pb | ≤0.003 |

| Fe | ≤0.02 |

| Cd | ≤0.002 |

| Sn | ≤0.002 |

| Si | ≤0.02 |

| Ni | ≤0.001 |

Zamak 4 General Mechanical Properties

| Mechanical Properties | Metric Value |

|---|---|

| Ultimate Tensile Strength | 317 MPa |

| Yield Strength (0.2% offset) | 221—269 MPa |

| Impact Strength | 61 J (7 J aged) |

| Elongation | 7% |

| Shear Strength | 214—262 MPa |

| Compressive Yield Strength | 414—600 MPa |

| Fatigue Strength (reverse bending 5×108cycles) | 48—57 MPa |

| Hardness | 91 Brinell |

Zamak 4 General Physical Properties

| Physical Properties | Metric Value |

|---|---|

| Solidification Range (melting range) | 380—386 °C |

| Density | 6.6 g/cm3 |

| Coefficient of Thermal Expansion | 27.4 μm/m-°C |

| Thermal Conductivity | 108.9—113.0 W/m-K @ 100 °C |

| Electrical Conductivity | 26-27% IACS |

| Specific Heat Capacity | 418.7 J/kg-°C |